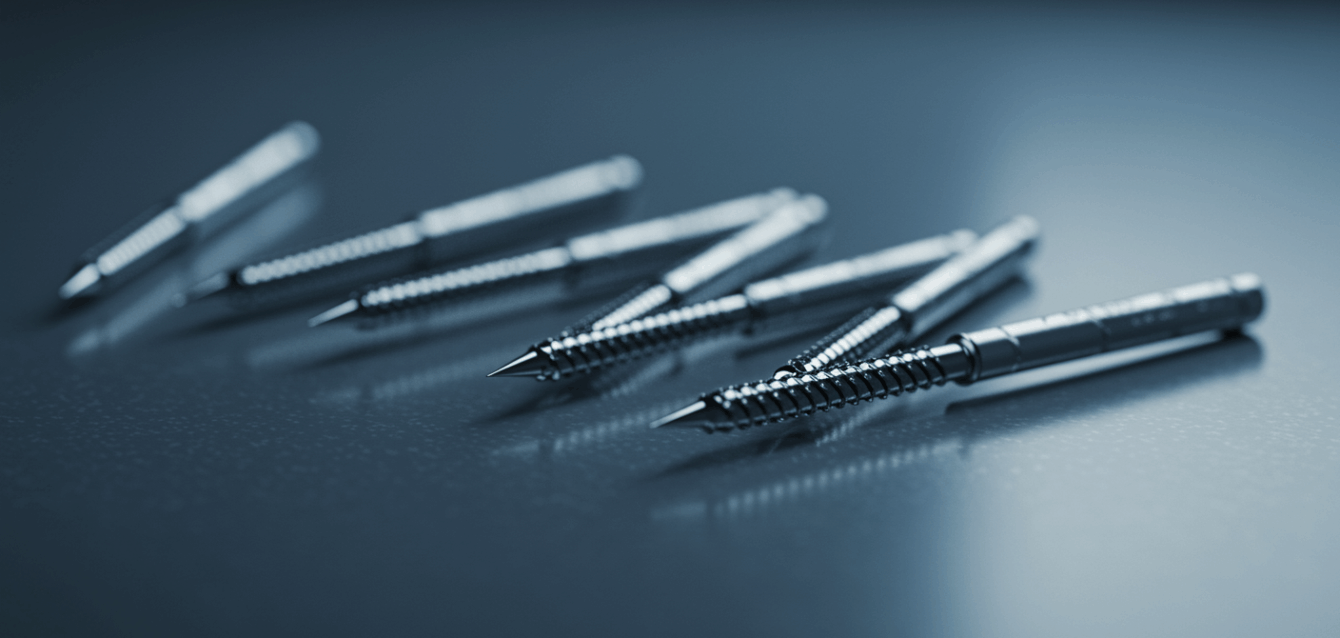

Despite technological disruptions in medical instrumentation, the hearth of needle innovation remains Japanese materials science and microfabrication. Japanese surgical-grade stainless steel, renowned for its purity and strain‑resistance, enables profoundly thin, sharp, and durable hypodermic needles. The fabrication process—rolling stainless steel sheets into micro‑precision tubing, floating to tighten tolerances, and conducting crack and straightness inspections—is executed with tolerances down to 0.001 mm in the highest-tier suppliers.

Moreover, firms like Kōno Seisakusho went further: producing needles under 0.03 mm to meet microsurgical demands, enabling suture work on vessels under 0.5 mm diameter under the microscope. This level of craftsmanship underlies Zelostat’s ultra-fine needle construction—combining thin walls for comfort and sufficient strength to maintain precision during insertion.

Zelostat’s ultra-low dead space hub is equally critical: engineered from fine steel and medical-grade polymers, it ensures that residual volumes post-injection are negligible—economically and clinically essential in dosage‑sensitive therapies. Meanwhile, every batch of Zelostat needles is produced in Japan, under stringent QC regimes and continuous improvement culture (Kaizen), delivering unmatched consistency on dimensions and antimicrobial standards.

As medical applications converge with regenerative therapies, aesthetic medicine, and immunotherapy, the demand for high‑quality steel-based injection tools remains undiminished. Zelostat’s combination of Japanese steel tradition and modern nano‑engineered manufacturing sets a benchmark for the future of injection device excellence.