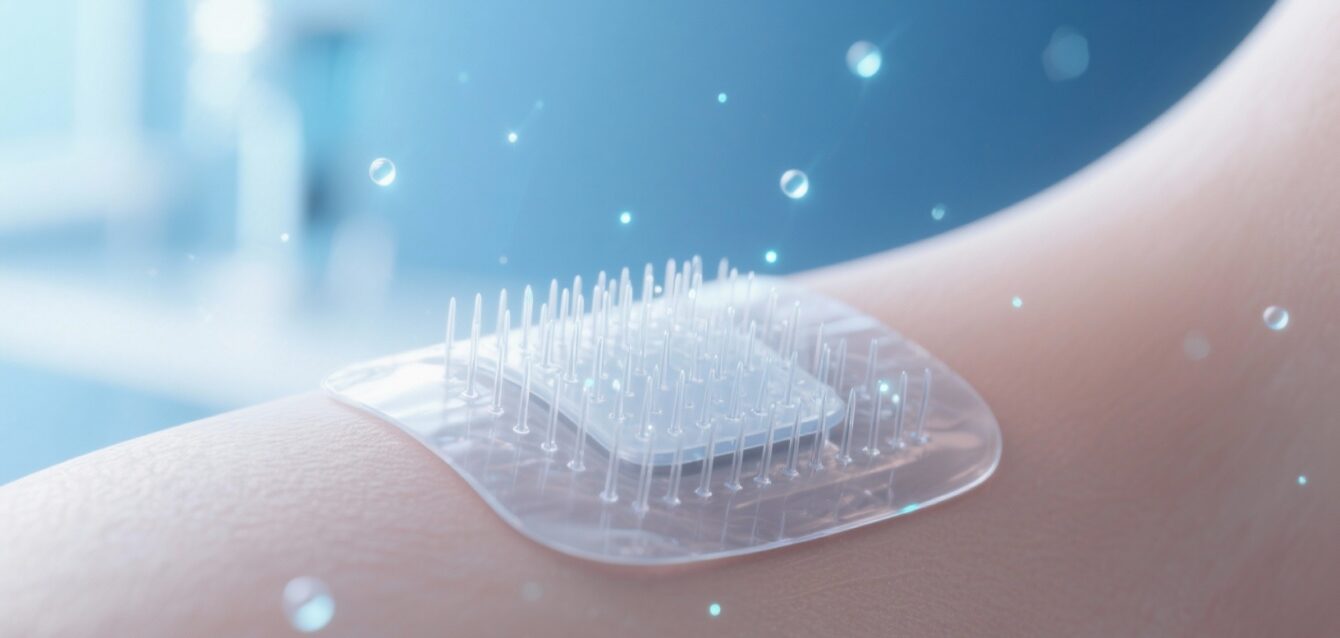

Microneedle (MN) microarray patches and high‑precision plastic microneedles are redefining non-invasive transdermal drug delivery, biosensing, wound healing, and cosmetic therapy. A recent Frontiers review highlights how microneedle arrays offer minimally invasive drug administration with enhanced patient compliance, reduced side effects, and even real-time biomarker monitoring when combined with biosensors. Furthermore, polymer-based microneedles now include dissolvable, hydrogel-forming, coated, and hollow types tailored to specific biomedical tasks.

Zelostat has begun to integrate polymer microneedle concepts into next‑generation designs. Unlike rigid stainless steel, advanced plastic or biodegradable microneedles can be engineered to dissolve at controlled rates, regulate penetration depth, and embed microelectronics for traceable dosage data. This opens up future scenarios such as smart insulin patches, sustained-release vaccine delivery, and cosmetic infusion devices with integrated sensors.

Plastic microneedles also align with trends toward home‑based self‑care and minimal‑hazard medical waste. Because they can be designed to dissolve after use, they circumvent sharps disposal issues and lower infection risk. The material compatibility with Japanese polymer molding technologies ensures high consistency, biocompatibility, and scalable manufacturing.

In PRP or cosmetic injection contexts, plastic microneedles hold promise to further reduce discomfort and streamline point-of-care procedures. Combined with Zelostat’s precision steel-based tools, a hybrid portfolio that spans from ultra-fine metal cannulas to smart, polymer microarrays positions ASTI at the forefront of innovation in medical device delivery systems.