ASTI Med Inovation

about usWhat is Zero Dead Space Technology?

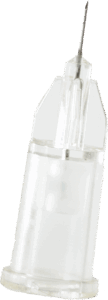

In traditional needles, “Zero Dead Space” refers to the small internal volume between the syringe and the base of the needle hub-where residual liquid remains trapped after an injection.

Inconsistent dosing and wasted product from residual fluid can erode practitioner confidence and patient trust — especially when using high-value injectables such as mesotherapy solutions, biopharmaceuticals, or regenerative treatments.

Zelostat eliminates this dead space with a patented elastic hub system, uniquely engineered to fill the gap between the syringe tip and the needle base.

This is accomplished through:

01-A medical-grade elastic body securely embedded within the needle hub

02-Dual-edged needle design: both the tip and the base of the needle are sharply pointed

03-The needle base pierces into the elastic material, forming a completely sealed and continuous fluid pathway

04-The elastic hub adapts to various luer-lock syringe types, maintaining strong airtightness regardless of syringe brand

technologyKey Advantages of Zelostat's

Zero Dead Space Needles

Zelostat vs Traditional Needles:

– Dead Volume: Eliminated through elastic hub vs Residual product remains.

– Injection Efficiency: Near 100% drug delivery vs Loss of product due to waste.

– Compatibility: Adapts to various syringes via elastic seal vs May leak or ‘pop off’.

– Safety & Comfort: Lower trauma, lower bleeding risk vs Thick needle wall, more pain.

– Sterile Integrity: Controlled ISO Class 8 production vs varies by manufacturer.

Precision Validation

0

%

Tests Conducted

0

+

Zero Dead Space

futureComparison of Diameters

The World's First

35 G Zelostat

Zelostat Needle / Convensional Needle

OD (mm): 0.16 / None

ID (mm): 0.105 / None

34G Zelostat

Zelostat Needle / Convensional Needle

OD (mm): 0.18 / 0.18 - 0.20

ID (mm): 0.12 / 0.10

31G Zelostat

Zelostat Needle / Convensional Needle

OD (mm): 0.25 / 0.26

ID (mm): 0.20 / 0.15

highlightsWhat Makes It Unique?

Zelostat’s patented structure-JP Patent #7650263 and pending in US, EU unlike any generic ‘‘Low Dead Space’‘ solution available.

Key differentiators include:

01

Dual-edged stainless steel needle embedded at both ends

02

Elastic material that precisely conforms to the syringe nozzle

03

Superior grinding and polishing technology ensures sharpness

,

04

No plastic hub dependence, avoiding detachment risks

japanese steel1250 medical expert & 500 companies use Zelostat to power their services

technology deep diveWhy It Matters in Clinical Practice

Economic Efficiency

With almost zero product loss, each syringe delivers exactly what you intend.

Patient Comfort

The 35G needle (phi0.16 mm) is one of the thinnest in the world, minimizing skin trauma.

Next-Gen Impact

Less waste per injection. More sustainable over time.

needle innovationZero Dead Space Technology (ZDS)

Traditional needles often trap residual product in the hub due to rigid connection points, leading to avoidable waste—especially problematic for high-cost medical or aesthetic solutions.

Zelostat solves this with its patented hub design, which uses a soft, elastic material instead of the hard plastic typically found in other needles.

This elastic interface allows the syringe to fit seamlessly into the hub:

• It compresses gently around the syringe tip, creating an airtight seal without leaving space for air or fluid to remain.

• As a result, nearly 100% of the liquid content is pushed forward into the needle, drastically minimizing product loss.

• The elastic body also adapts to minor variations in luer-lock syringe tips, ensuring compatibility and consistent sealing performance.

• Additionally, the bottom-end of the needle is sharp and securely embedded into the medical-grade elastic body, preventing needle popping and enhancing stability under pressure.

• This secure dual-ended design, where both ends of the needle are edged, contributes to robust attachment and optimal flow control.

Zelostat solves this with its patented hub design, which uses a soft, elastic material instead of the hard plastic typically found in other needles.

This elastic interface allows the syringe to fit seamlessly into the hub:

• It compresses gently around the syringe tip, creating an airtight seal without leaving space for air or fluid to remain.

• As a result, nearly 100% of the liquid content is pushed forward into the needle, drastically minimizing product loss.

• The elastic body also adapts to minor variations in luer-lock syringe tips, ensuring compatibility and consistent sealing performance.

• Additionally, the bottom-end of the needle is sharp and securely embedded into the medical-grade elastic body, preventing needle popping and enhancing stability under pressure.

• This secure dual-ended design, where both ends of the needle are edged, contributes to robust attachment and optimal flow control.

This innovation is not just a design improvement-it is a patented breakthrough that ensures

maximum product utilization with unmatched injection efficiency.

needle innovationBehind the Technology: Zero Dead Space (ZDS)

At the core of Zelostat’s innovation is its Zero Dead Space Technology, a solution developed to eliminate product waste at the needle hub.

• The syringe connects not to a rigid plastic base, but to a soft, elastic component inside the needle hub. This elastic body compresses tightly around the syringe tip, eliminating gaps where residual fluid would otherwise remain.

• In addition, the base of the needle is also sharp, allowing it to pierce and anchor securely into the elastic body. This ensures a tight seal and stable connection.

• The result is near-total delivery of the injectable material, significantly reducing waste and maximizing dosing accuracy—especially important when using high-cost or small-volume products.

• The syringe connects not to a rigid plastic base, but to a soft, elastic component inside the needle hub. This elastic body compresses tightly around the syringe tip, eliminating gaps where residual fluid would otherwise remain.

• In addition, the base of the needle is also sharp, allowing it to pierce and anchor securely into the elastic body. This ensures a tight seal and stable connection.

• The result is near-total delivery of the injectable material, significantly reducing waste and maximizing dosing accuracy—especially important when using high-cost or small-volume products.

Technical Features

• Ultra-thin, super sharp cannula for minimal resistance during penetration

• Elastic hub interface that adjusts to fit different syringe tips tightly and securely

• Both ends of the needle are edged, providing a secure hold within the hub and ensuring mechanical integrity

• Minimized dead volume, thanks to the integrated elastic component that fills otherwise empty space

• Smooth internal bore that allows lower injection pressure and faster delivery

Manufacturing Excellence

Zelostat needles are manufactured in Japan at ASTI Corporation’s ISO Class 8 cleanroom facility,

ensuring sterile, high-precision production under strict quality controls. The manufacturing process is overseen by engineers specialized in microneedle assembly, and includes:

• Real-time detection of defects such as clogging, bending, and leakage

• Quality checks for packaging integrity and needle tip uniformity

• Advanced grinding technology to achieve ultra-sharp bevels

• Use of high-grade, Japanese stainless steel for durability and biocompatibility

A Needle That Reflects Engineering Precision

Zelostat is not just another microneedle-it’s a complete redesign of what an injection needle can be. It brings together fluid efficiency, comfort, and craftsmanship in one cohesive solution.

Whether used for aesthetic treatments, regenerative medicine, or dermatological therapies, Zelostat aims to deliver maximum performance with minimum waste.